Flintstone Blast Mats in use at a civil contruction for an underground railway.

Blasting mats can be made of rubber, wire, or rope products. FLINTSTONE BLAST MATS are produced from the rubber tread of steel belted truck tyres, laid flat in two overlapping layers in brickbat style, and sewn with 6 lengths of 14mm galvanised steel cable, with galvanised fittings. The steel belting embedded within the vulcanised rubber gives our mats extreme strength and penetration resistance, and the thickness and density of the rubber provides the necessary weight, protection, and stability.

Often required in the mining and civil engineering, a heavy, tear resistant blasting mat is used to cover the surface, and sometimes the face, of a blasting area to prevent the dangerous projection of rock fragments.

The weight in the solid rubber, the strength of the steel belting, and the quality steel rope cables, make our blast mats a long lasting value for money must-have for many blasting projects.

Blast mats can also be utilized in many other operations from road and track protection and machinery pads, to subsea uses, temporary boat ramps, swamp mats, and more.

Our manufacturing capabilities allow us to produce various size steel cabled, steel belted, rubber mats from 1.0 m x 1.0 m to maximum 3.1 m x 7.0 m and weight is up to 1400 kg. Our mats are at least 60kg/m2, giving them the necessary weight to perform the task.

Flintstone Blastmats are very competitively priced, and can be shipped anywhere in the world.

Why use a blastmat?

With flyrock, prevention is better than interception!

Australian Standard AS2187.2-2006 states in Section 12.3: "Where protection from the possibility of fly is necessary, blasting mats or other suitable controls shall be used."

A well-designed blast will always be improved by having the increased safety factor provided by the use of blast mats. Mats are an essential addition to even the best of blasting designs in sensitive areas, where flyrock poses a risk of injury to persons or damage to property.

A single flyrock incident can result in death or serious injury, and property damage ranging from minor to serious.

Just one direct hit to persons or third party property (or even a near miss) can result in personal tragedy, legal implications, licence suspensions, and increased insurance premiums.

The strong and heavy construction provides the weight and protection necessary to protect the surrounding environment from flyrock, while allowing gases generated by the explosion to pass through, and vent safely to the atmosphere.

The blast mats have the added benefits of reducing the quantity of airborne dust particles and lowering the transmission of airblast overpressure.

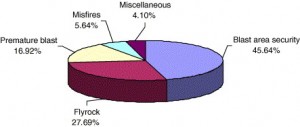

A study of 412 mining industry lethal and non-lethal accidents in North America completed in 2001 found that 27.7% of these accidents were caused by wild flyrock beyond the clearance zone and 45.6% of these accidents were caused by localised flyrock within the clearance zone. In this study, flyrock was responsible for more deaths and injuries than all other causes put together.

Blast mats are not a substitute for inadequate stemming, and are not designed to overcome poor blast design.

What is the lifetime of our mat?

If you try hard enough you can blow anything to bits!

So many factors affect the life of any product, but we offer a strong well-made product with a proven record for strength and durability.

Mats hung in front of the face generally incur increased wear and tear as they tend to get buried under the muck pile and can suffer damage during recovery, dependent on the blast result and the methods of retrieval.

Blast mats placed on the surface of properly stemmed blasting areas have an indefinite life provided they are handled and placed with due care.

Our mats are extremely durable due to the heavy construction and 14mm cable stitching ; attributes which also make them so effective.

The steel cabling and lifting loops make our mats practically “operator-proof” whether used in blasts or positioned and repositioned many times over for other uses such as track and road carpeting, machinery pads, or water edge ramps, plant and equipment, or mudmats.

With well-designed blast plans and sensible contractor handling such as removing the bulk of rock from buried mats after the blast rather than hooking and pulling out through the broken rock, our mats have been shown to last over a hundred blasts, and still counting.

Safety

When blasting in urban areas or near sensitive assets, both the explosives and blasting regulator in your jurisdiction, and your insurance company, will require you to take all reasonable and necessary steps to prevent the dangerous projection of rock fragments.

If you could have used blasting mats but chose not to, can you sustain an argument that you “took all reasonable and necessary steps”?

The five environmental hazards from blasting are ground vibration, airblast overpressure, dust, fumes, and flyrock. There are prescribed upper limits for vibration, overpressure, dust, and fumes. The use of blasting mats is an effective control strategy.

The prescribed upper limit for flyrock is zero.  Can you afford not to be protected?

Can you afford not to be protected?